Why flaxseed/linseed oil need low-temperature physical press?

Flaxseed oil contains an adequate amount of linolenic acid and the oils is usually extracted by low-temperature physical squeezing in the flaxseed oil production line. Because flaxeed oil has balanced proportion of linoleic acid, which is 1:4. and it is scientifically proven that when the ratio of linolenic acid to linoleic acid is 1:4, the human body can be in the healthiest state, ans it is very difficult for various external bacteria to invade. Flaxseed oil can meet human health standards.

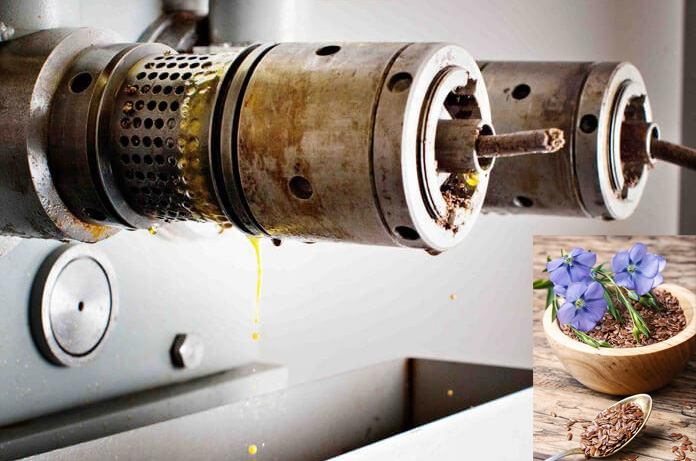

However, linolenic acid is highly heart-sensitive and easily oxidized. When the critical temperature is exceeded, the activity oflinolenic acid begins to be destroyed. Therefore, when making flaxseed oil, it is necessary to choose the physical pressing method at low temperature without any heating treatment. Low-temperature physical squeezing retains the activity of linolenic acid, and no additives in the whole process to maintain the natural quality of raw materials. Second, the physical pressing temperature is lower than the melting point temperature of the wax, so that the pressed flaxseed oil is free from the”dewaxing” procedure and avoids the damage caused by the dewaxing process.

The steps of flaxseed oil press line are mainly: flaxseed selecting--screening--cleaning up impurities--crushing--flaking--conditioning--normal temperature pressing--residue separation--degumming--dehydrating--debittering--crystallization--cryogenic filtration--physcial pressed linseed oil.