Technology news

What oil equipment is needed to remove impurities in the oil machinery production line

2024-09-26

What oil equipment is needed to remove impurities in the oil machinery production line

Manufacturers who invest in oil machinery equipment know that the first step of oil machinery extraction is the pretreatment stage of oil. Impurities in oil include mechanical impurities, colloid-soluble impurities, fat-soluble impurities, trace impurities and water. Today, I will briefly introduce these types of impurities and what equipment is needed to remove these impurities in the oil production line. Let's take a look.

First of all, mechanical impurities refer to solid impurities that are insoluble in oil. Oil is obtained by pressing or leaching. Crude oil is obtained by pressing or leaching. Mechanical impurities are solid impurities such as mud, embryo powder, cake residue, fiber, grass clippings, etc. mixed in the oil during oil production or storage. Because it is insoluble in oil, it can be removed by simple process treatment such as filtration and sedimentation.

1. Pretreatment equipment: such as cleaning and stone removal equipment, which is used to remove impurities and stones in oil raw materials; crushing equipment, which is used to crush large pieces of oil raw materials into small pieces suitable for processing; embryo pressing equipment, which is used to press the crushed raw materials for subsequent oil pressing operations.

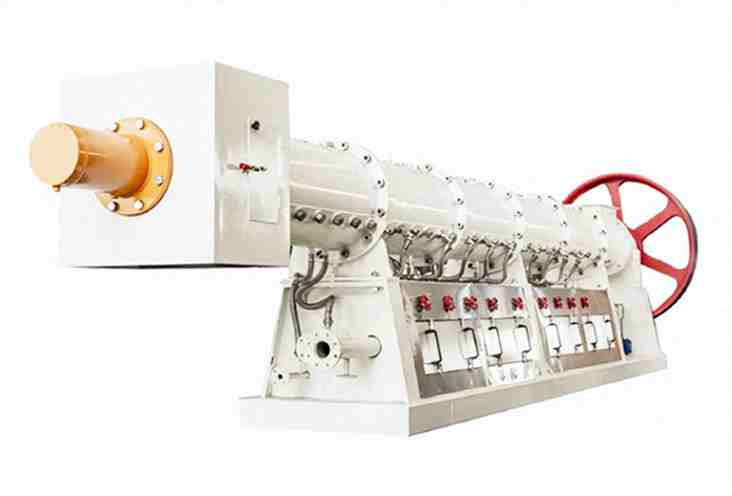

2. Oil pressing equipment: including oil press and corresponding auxiliary equipment, used to extract oil from raw materials.

3. Crude oil filtering equipment: used to remove impurities and solid particles in the extracted crude oil.

4. Refining equipment: including acid-base reaction oil tank, vacuum dehydration equipment, decolorization equipment, vacuum deodorization equipment, white clay filter, etc., used to refine crude oil into edible or industrial grade oil. These equipment can remove impurities such as fiber, phospholipids, pigments, free fatty acids, moisture, wax, etc. in crude oil that are harmful to the human body and affect the quality of oil.

In addition, there are some auxiliary equipment such as steam boiler (thermal oil furnace), oil pump, lifting equipment, etc., to provide necessary auxiliary support for the entire production line.

Please note that the specific configuration and parameters should be selected and adjusted according to actual needs and different production processes. In actual applications, other auxiliary equipment and facilities may also need to be selected according to the needs of specific production lines, such as edible oil dewaxing equipment, grain processing equipment, grain drying equipment, etc.