Municipal Solid Waste Incineration To Power

Municipal solid waste incineration power generation core equipment is waste incinerator, waste incineration power generation of municipal solid waste, incineration of electricity in addition to 13 ℅ for their own use, the rest can be incorporated into the grid for enterprises to create economic benefits and reduce the burden on the government. The development of urban waste thermal power station and the number of urban population also has a certain relationship, because the main power plant is continuous,which need to have enough quantity of waste to ensure continuous operation. At the same time, considering the quantity and quality of waste will vary with the seasons. According to the urban population, the average amount of garbage per person per day is about 1 kg (slightly more developed countries), the urban population is more than 1 million, the daily production of urban waste in more than 1,000 tons, you can ensure stable power generation. Generally believed that when the heat value of garbage is greater than 3349kJ / kg, you can burn by natural means. The content of organic matter in municipal solid waste in the area of burning gas is quite high, generally over 50%, and high above 80%. A large number of organic waste is valuable resource, it can extract useful substances, is the main combustible components in the garbage.

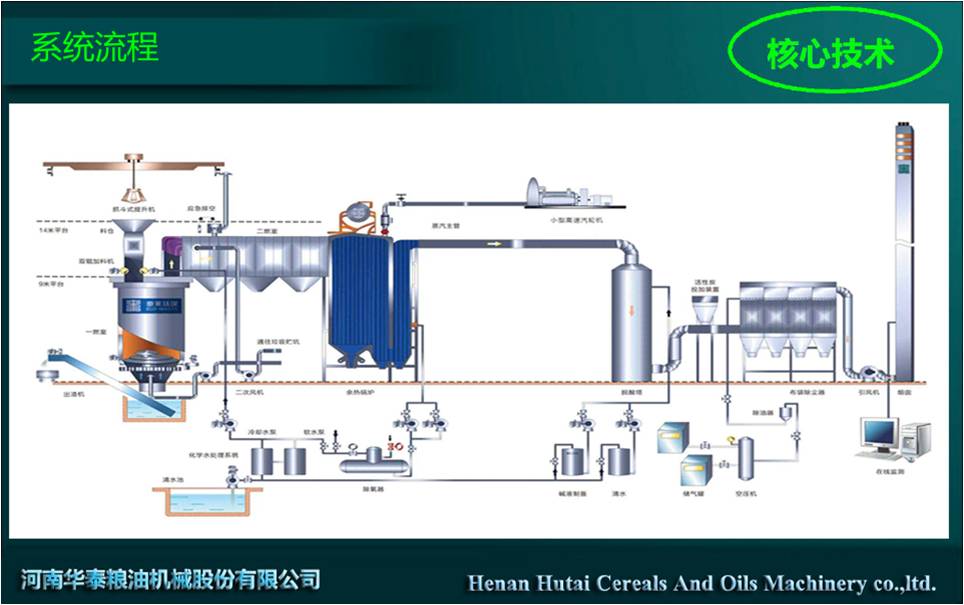

Municipal solid waste incineration power generation is using of incinerators in the combustible materials in the garbage incineration, high temperature incineration after the elimination of a large number of garbage in the harmful substances, to harmless, reduction of the purpose, while the use of recycled heat Heating, power supply, to resource-based.

Garbage is a waste heat boiler thermal power station equipment, is also the key to the development of waste thermal power station. As the garbage is a certain corrosive fuel, water, calorific value of unstable waste, and thus the garbage boiler and its combustion equipment in the design of its certain specificity. As the waste heat value is low, and the moisture content is high, therefore, the performance of the combustion equipment is the key to the garbage boiler.