Pyrolysis and Gasification of Municipal Solid Waste

In this case,Pyrolysis of municipal solid waste gasification Pyrolysis gasification technology is called the third generation of waste treatment technology. In the early 1990s, France, the United States, Britain, Germany, Switzerland, Japan and Sweden took part in the development of this technology, and in the late nineties began to be used in developed countries. Our company is engaged in new materials and industrial promotion of the field of high-level research, technology transfer, industry promotion of new enterprises.

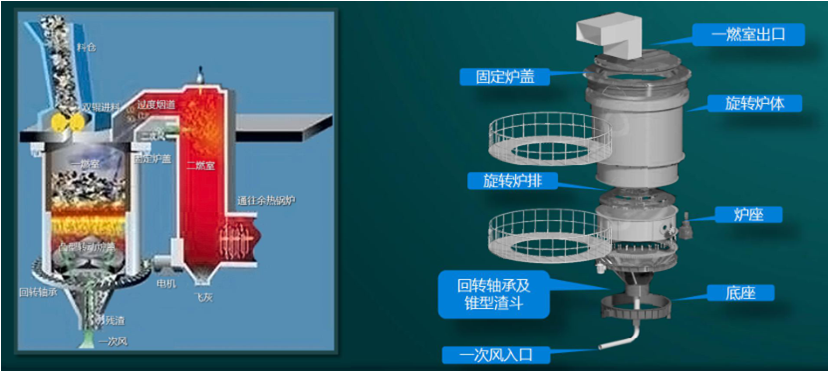

Pyrolysis and gasification process of municipal solid waste Description:

Pyrolysis gasification technology is a new waste disposal method: its biggest advantage is to overcome the use of incineration method will produce the shortcomings of dioxin. This technology creates a new technological process by combining several traditional, mature technologies. It combines innovative pyrolysis technology and traditional high-temperature oxygen gasification technology to simulate the chemical process in the formation and gasify the waste. Pyrolysis gasification technology can handle all types of waste, such as used electrical appliances, batteries, printer cartridges, disposable infusion sets, injection products, etc., without any prior sorting. After the garbage is crushed, the organic components of the refuse are vaporized at a high temperature of about 400C, and the inorganic components are melted, and then rapidly cooled to 75C in a short time to avoid the regeneration of dioxins, and the waste is completely converted into Synthesis gas and recyclable micro-solid residue, garbage in the invalid components are melted and hardened to form a useful new wall materials.